Never a Dial Moment

The crafts that Rolex employs to perfect its dials are always accompanied by innovative technologies, often developed by the brand itself for a synergistic experience. Where one brings quality, the other offers utility.

Take its applied indexes, for instance. The perfectly polished indexes are hand-applied across all its dials, and the appliques range from baguette diamonds to gold or platinum markers. On its Professional and most classic models, the applied indexes are filled with Chromalight that emits a blue light that is exceptionally bright and long-lasting in dark conditions. Chromalight is a crystal made up of aluminium and other rare elements that make it phosphorescent, combined with a resin and then applied by hand to the appliques carefully, for its exceptionally bright and long-lasting luminosity, far outperforming watchmaking norms.

Likewise, Rolex’s classic dials feature a sunray finish, a traditional brushing technique, combined with modern electroplating solutions to create vivid, colourful displays that thrill. On occasion, it also turns to classic artistic crafts such as enamelling.

One example is the moonphase display on the Cellini Moonphase that uses grand feu enamelling to bring the midnight blue of the night sky to life. The enamel disc is made by first rendering the right shade of blue, mixing the colour and then hand-painting the disc. It is then fired up in a kiln at a high temperature to melt the enamel and produce the stunning moonphase counter on this classic Rolex timepiece.

Across all of Rolex’s watches, the visual display of time is enhanced through the artistic use of materials, colours, patterns or accents. This balance between innovation and design is further enhanced by iterative expressions that lets the brand discover what their customers truly desire, which they bring to life over time.

Making the Case for Rolex

As a truly verticalised watchmaker, Rolex makes its own watch cases.

In the early 2000s, Rolex set up its own state-of-the-art foundry where it casts its gold. This unusual step for a watchmaking brand allows Rolex to ensure that only the finest of this precious metal is used in its luxury timepieces.

Take the 18K Everose gold alloy. It is made from pure gold mixed with silver, copper and other noble metals in a crucible, heated to over 1,000°C into a liquid alloy. This is then poured over a graphite sieve that’s just two atoms thick, to form gold beads that are then fashioned into rods. The same process goes for 18K yellow and white gold alloys. The unique formula of its alloys ensures the everlasting shine of its precious metal watches, from the case middle to its bracelets.

Even its Oystersteel models stand apart from others in the industry. The Oystersteel used in Rolex timepieces since 1985 is made with 904L steel, a superalloy whose excellent anti-corrosion properties are comparable to those of precious metals. Specially developed by Rolex, Oystersteel is not only extremely resistant but also offers exceptional sheen. Rolex watches manufactured with this special steel retain their beauty even when exposed to the most extreme conditions.

Gold is coveted for its lustre and nobility. Steel reinforces strength and reliability. Together, they harmoniously combine the best of their properties. A true Rolex signature, Rolesor has been featured on Rolex timepieces since the early 1930s, and was trademarked as a name in 1933. It is one of the prominent pillars of the Oyster collection.

Finally, there is the most exclusive of classic watchmaking materials: platinum, which has incredible lustre and elegance while being highly corrosion resistant. Typically, this is reserved for classic models but in recent years, Rolex has also introduced precious metal materials into its Professional category of timepieces.

As work and play become ever more intertwined in our lives, the Oystersteel, Rolesor and platinum range of watches have become a favourite among aficionados today. The latest watch to join this privileged status is the Oyster Perpetual Explorer, now in Oystersteel and 18K yellow gold Rolesor.

Technicolour Dreams

The development of new materials has defined modern watchmaking. Within Rolex, such innovations have taken years, even decades, to come to fruition. This is particularly true of one of its most popular components — the Cerachrom bezel.

Ceramics have been used in watchmaking for over 30 years, but few brands have pushed the aesthetic boundaries of the material as far as Rolex has. Its durability makes it particularly alluring for parts of the watch that are frequently exposed, like the bezel. While traditional zirconium oxide ceramics are austere in colour, Rolex’s Cerachrom bezels are vividly coloured thanks to its independent research in the material. Fashioned from extremely hard ceramic material, it is virtually impervious to scratches, and its colour is unaffected by the ultraviolet rays of the sun.

With the robustness and durability of its watches in mind, Rolex developed and patented the Cerachrom bezel insert and the Cerachrom bezel for specific Professional models in the Oyster collection. These can be found on the Oyster Perpetual GMT-Master II models that are unique because of the intensity of the colours used as well as the method used to produce them. Using alumina as a base and experimenting with other metal oxide mixtures, Rolex successfully engineered a striking opaque red tone in a ceramic.

Going further, it developed its own methods for creating its first two-colour, single-piece ceramic bezel insert — a world first. These are moulded and then heated in one seamless process to create the two-coloured bezel ring. The distinct separation of colour is the most challenging as it cuts across two numerals on the 24-hour ring, in addition to the heating process that can cause the ceramic to crack as it shrinks. As there are multiple factors that can affect the production process, this is as much a craft as it is a science.

Since the introduction of the first Cerachrom bezel insert in 2005 on the Oyster Perpetual GMT-Master, a full range of coloured bezels have emerged on Rolex models, thanks to its continuous research on the components.

Getting Buffed

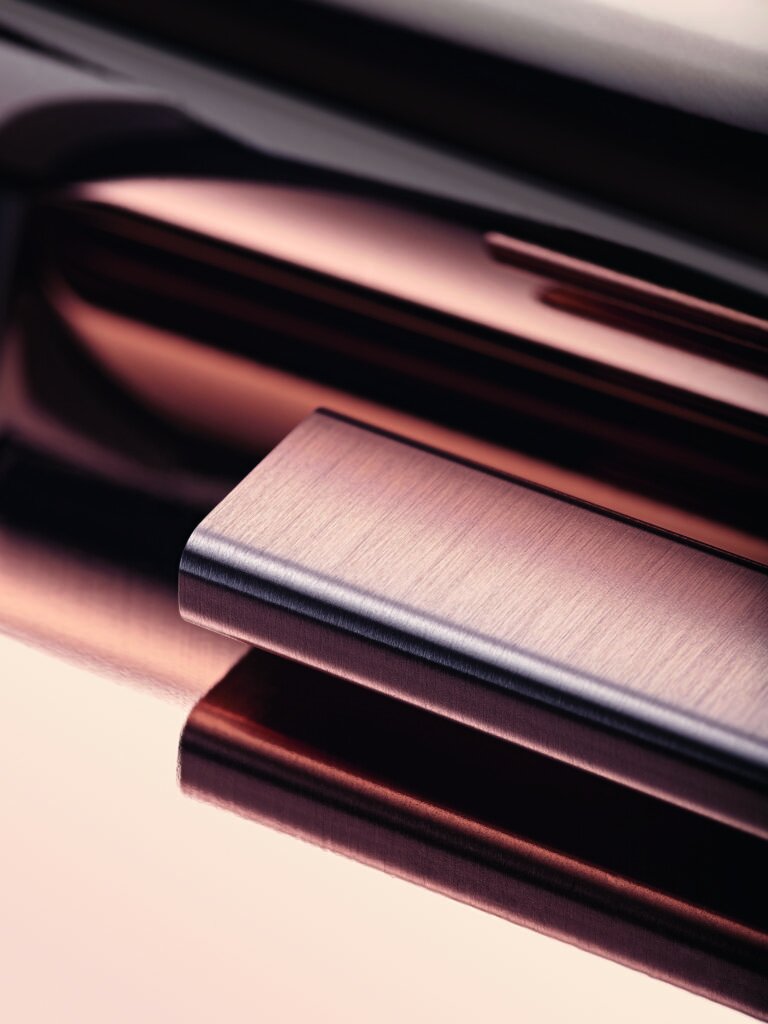

In the process of transforming a block of precious metal into a Rolex watch, thousands of steps are needed. Every component of a Rolex watch — even parts that are hidden from view, like the inner case — is delicately finished.

This process does more than add sheen and shape to the timepiece, it also removes any abrasive material that may affect a movement’s performance. Polishing is one of the most telling stages in the making of a Rolex watch, providing the metal surfaces with that perfect final lustre and smoothness.

Despite the advent of automated technology, the process remains a highly skilled craft that involves tremendous precision. Each step in finishing the watch requires patience and a steady hand, but also plenty of care. The polisher’s (otherwise also known as a termineur or finisher) craft is honed through the years before it reaches a level of proficiency and assurance that corresponds with the unyielding standards at Rolex.

Each material and component demands a unique polishing approach. Gold is softer and easier to shine but can be easily misshaped if not done with precision; platinum is malleable but easily scored through excess pressure or friction; as for Rolex’s proprietary Oystersteel, it demands more time and strength to achieve an even lustre.

At Rolex, polishing is done via automated processes and supplemented with the human hand, dividing the polishing process into two: surface preparation, mainly carried out by controlled machines, followed by surface finishing that is done predominantly by hand.

During automated surface preparation of the freshly machined case and bracelet components, skilled polishers will carry out visual checks of the parts before the computer-controlled movements of the robot arms in the booths simulate the original human handling of manual polishing. Surface finishing, however, is generally done by polishers working on polishing lathes fitted with softer discs or a polymer pink brush wheel used to obtain a satin finish.

A Gem-Packed Experience

Rolex houses many crafts across its four manufactures, the oldest craft being gem-setting, housed in its Chêne-Bourg facility. The gemstones that it acquires are carefully inspected with specialised machines and individually checked by gemmologists to verify their authenticity and quality, before being sorted by colour for consistency. Rolex only uses diamonds that are internally flawless and fall within the colour grades of D to G — the finest hues on the Gemological Institute of America’s scale.

Once approved by the gemmologists, the precious stones are then entrusted to the gem-setters. With the precision of a watchmaker, they set each stone, one by one, onto the watches. A gem-setter’s craft is multifaceted. First, decisions are made with designers in the Creation Division about the colours and arrangement of the stones.

This is a subtle exercise in finding a balance between aesthetic and technical requirements. Then follows a consultation with the case and bracelet engineers. Together, they study the future placement of the stones in order to prepare, to the nearest micron, the gold or platinum into which the stones will be set.

An excellent example of this work is revealed in the new Oyster Perpetual Lady-Datejust, available in 18K white or yellow gold and fully set with diamonds on the case, case sides, lugs, dial and President bracelet. A total of 1,089 diamonds are used on each watch, making it a work of haute joaillerie as well as watchmaking.

This watch truly showcases Rolex’s mastery of gem-setting, especially on the President’s bracelet, as every link is curved. The gem-setter must line the diamonds precisely on the curved surfaces while ensuring that each setting is properly secured to each diamond. Furthermore, each row of diamonds must also align with other links, making it even more challenging, and with no room for error.

To Mathematical Precision

Gem-setting isn’t simply a craft, it’s also a science. Beyond the initial inspection of each stone, the Oyster Perpetual Lady-Datejust’s case middle and dial are also set in diamonds. This means the layout of each diamond must be carefully considered to take the applied numerals on the dial into account, as well as the sides of the case middle as it tapers into the lugs.

To achieve this, a digital positioning of each gemstone is first mapped out to ensure that every part of the watch is fully clad in diamonds, including the space needed for claws to secure each gemstone. This informs the gemmologist how many gemstones of each size are required for every watch. These diamonds have to be further matched for colour, before they are passed on to the gem-setter and placed in position. On watches like the Oyster Perpetual Lady-Datejust or Oyster Perpetual Day-Date 36, this is done with mathematical precision, a process that is as technologically impressive as it is breathtaking.

When it comes to rainbow-graduation bezels, each sapphire has to be individually selected to ensure the graduating change in colour is consistent and evenly spaced. The gemstones also need to be carefully calculated with precision to ensure that the pressure on each gemstone is evenly distributed and each baguette-cut stone is precisely sized to ensure a perfect fit on the bezel.

Throughout its history, Rolex has created timepieces that evoke desire, excitement with a vibrant expression of time, inspired by the worlds that its timepieces inhabit — across land, air and sea — and the colours of the natural world that it brings to its watches. This is even more true with its newest timepieces, dreamt up by its creative team and mastered with the latest innovations in watchmaking technology.

From the stately Oyster Perpetual Explorer to the adventurous Oyster Perpetual Explorer II, the stylish motifs of the Oyster Perpetual Datejust 36 to the sophisticated grace of the Oyster Perpetual Lady-Datejust, each timepiece is created by fusing science with the art of timekeeping.

That is the unique formula of Rolex: timepieces that are as precise as they are precious, as long-lived as they are long-lasting, both in style and function.