If you’re a millennial foodie, chances are that you already know about Fossa Chocolate. Their slim, rectangular bars with unusual flavours such as Salted Egg Cereal and White Sesame & Seaweed are regulars on the shelves of cafes and shops all over Singapore. Even more impressive, however, is the fact that, with fewer than five years of operation, Fossa Chocolate has also expanded its reach to several stores in Hong Kong, Japan, France, the Maldives, as well as 147 locations across the US and Canada. So — how did they do it? And why?

We explore just that in our first edition of The Makers, a new series where we explore the many home-grown artisanal products and crafts that are quietly enriching Singapore’s cultural landscape.

How It All Began

Fossa was started in 2017 by a trio of friends: Jay Chua, Charis Chia, and Yilina Leong. As the story goes, they were blown away by the intense flavour of a single-origin chocolate bar they had tried, which was made from cacao grown in Madagascar. It had notes of raspberries and almonds, even though there were only two ingredients on the list — cocoa beans and sugar.

At the time, artisanal bean to bar chocolates were nigh impossible to find, even in food-obsessed Singapore. So the trio decided to make their own.

They started sourcing the raw cocoa beans, sorting and peeling each batch by hand and roasting them in their home ovens before grinding and tempering them into bars of chocolate. Selling those bars was never intended to become a full-time business, says Chua, one of the company’s two main chocolate makers. “I just treated it as a weekend hobby… it was bleeding cash, but we were fine because it was something that we thought was fun to do.”

Their fun-to-do bean to bar process is what has garnered them crowds of fans. But it was also what made growing the business challenging in the beginning.

“Craft chocolate was at its infancy when we first started,” says Leong, who manages Fossa’s marketing and business development. “When we shared our products with customers, we would more often than not be asked why our chocolate was so expensive — “it’s $10 for a small bar, compared to what I can get in a supermarket.””

Bean to bar chocolate specifically refers to chocolate that has been crafted by a chocolate maker from scratch using cacao beans, rather than from pre-prepared commercial couverture chocolate, which is the stuff usually used by companies whose products are stocked in most supermarkets. (Mast Brothers’ 2015 scandal aside.)

To be clear, there is nothing wrong with supermarket chocolate — Cadbury and Lindt can still satiate the palate, and can be nostalgic and comforting, since they will always taste the same, year after year.

On the other hand, bean to bar chocolate will have flavours that are more complex and that are unique to each bar. This is even more pronounced in single-origin chocolates, which use beans produced by a single farmer, and captures flavours unique to that terroir, much like single-origin coffee, or wine — it’s why we talk about Burgundies and Bordeaux, and not just white or red wine.

And, just like any gourmet coffee, wine, or cheese maker will tell you, it all starts with great ingredients.

(Image: Fossa Chocolate)

Fossa mostly sources their cacao beans directly from smallholder farmers, who will harvest the cacao fruit pods when they are ripe and process them accordingly, extracting, fermenting and drying the cacao beans in ways that will enhance their eventual flavour. According to Chua, this direct connection to the farmers also sometimes allows them to ask farmers to experiment with the fermentation and drying process — just to see what happens.

Of course, the farmers would likely not do that for just any customer. Fossa’s relationship with the farmers is one built on trust and mutual respect. For one thing, the trio makes sure to pay the farmers cash.

“Traditionally, the farmers are always the ones who are being owed money, always promised credits, which may sometimes take years to pay back.” Chua shares. “But we want to make sure that the farmers, who have put in a lot of hard work, are able to have the money to pay for their children’s education…” According to Fossa, commodity prices of cacao are often so low that most farmers can barely survive off cacao alone. That is why the company also pays above-market prices for their cacao, so that the farmers will be motivated to continue the work that they do, and perhaps even improve the quality of the cacao they produce.

One such farmer is Pak Eddy — Pak meaning “Mister” in Bahasa Indonesia — a cacao farmer based in Yogyakarta who is, according to Fossa, one of the best cacao farmers in Indonesia. Pak Eddy started his cacao farm in 1992 and has since continually experimented with ways to better his farm and his crops. As of last year, Pak Eddy has started transitioning it to an organic farm, supplementing soil nutrients with fermented cocoa pods that would otherwise go to waste.

-

Pak Eddy

(Image: Fossa Chocolate) -

Pak Eddy single-origin chocolate.

(Image: Fossa Chocolate)

His efforts, along with the stringent processing that Fossa undertakes after receiving his cocoa beans, mean that the single-origin chocolate bar bearing Pak Eddy’s name was awarded bronze at the International Chocolate Awards last year.

Bean To Bar

After the cocoa beans arrive in Singapore from the farm, it takes seven steps to turn them into a bar of chocolate. Beans are sorted to remove defects and detritus, roasted to develop flavour, cracked into cocoa nibs, winnowed to remove husks, ground until completely smooth, mixed with sugar or other ingredients, and finally tempered into bars.

Fossa puts a lot of work into each stage of the process, which enhances the flavour and quality of the chocolate. For instance, the cocoa nibs are ground for up to 5 days to develop the flavour of the chocolate and to make sure that it is completely smooth, with no grittiness when it melts on the tongue. Many other manufacturer’s chocolates have a degree of grit simply because a shorter grind time means bigger cost savings.

-

Cocoa nibs are ground for up to 5 days to produce smooth liquid chocolate. They can also be eaten as a healthy snack. -

Chocolate in the process of being milled to smoothness. -

Smooth ground chocolate. (Image: Fossa Chocolate)

Once the chocolate is ground, the real fun with flavour begins.

As Chua put it, “experimentation is part of our DNA”, and this spirit really comes to the fore when it comes to Fossa’s flavoured chocolates.

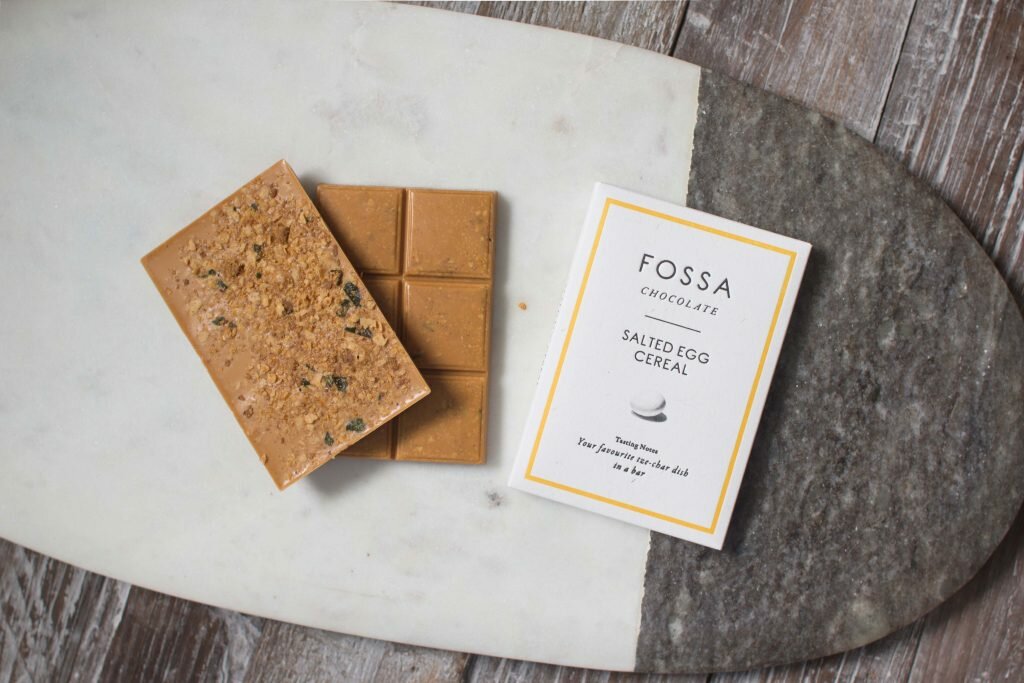

Chia, who has a background in pastry making, was the first to suggest experimenting pairing their chocolates with local flavours. Fossa’s Salted Egg Cereal blonde chocolate, for instance, started because of her love for salted egg cereal prawns.

“Me and Jay, we both like to try different cuisines,” Chia says about their inspiration behind their unusual flavours. “And our chocolate is usually inspired by the things we love to eat.”

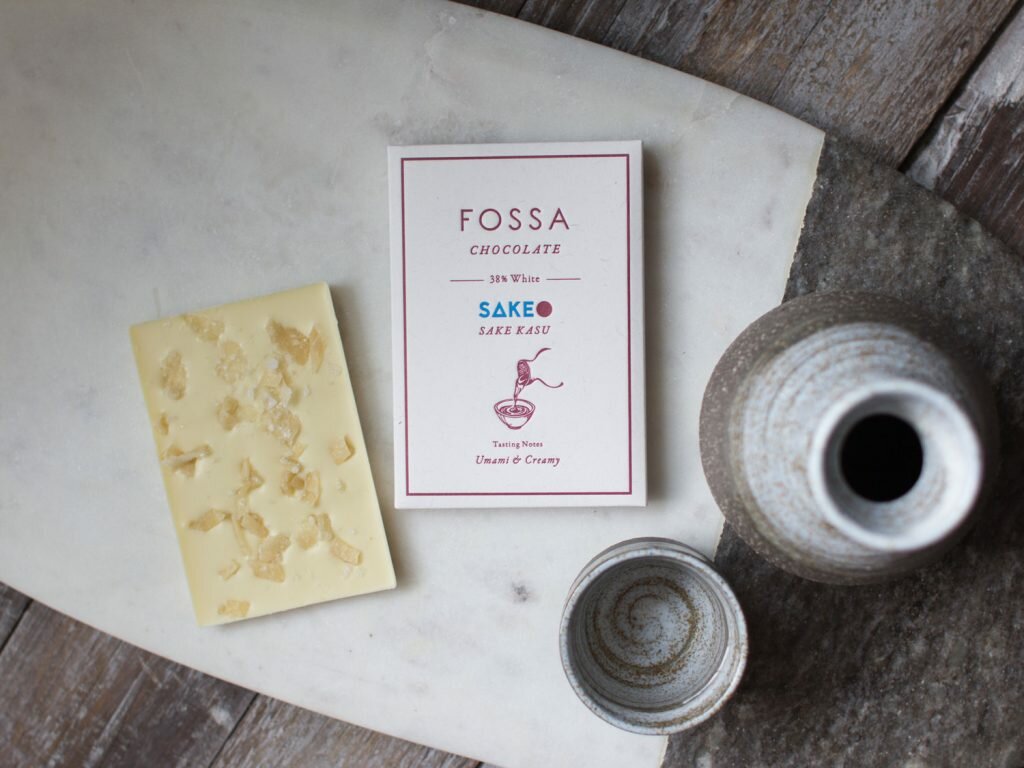

That philosophy has spawned flavours such as Chilli Peanut Praliné, which was inspired by satay sauce, and Shrimp and Bonito, which was inspired by a visit to Tsukiji market in Tokyo. Other unusual flavours include White Sesame and Seaweed, Lychee Rose, as well as Sake Kasu, which is made with sake kasu left over from the sake brewing process.

(Image: Fossa Chocolate)

-

Shrimp and Bonito chocolate, inspired by a trip to Tokyo’s tsukiji market.

(Image: Fossa Chocolate) -

Sake Kasu white chocolate — also available in dark chocolate.

(Image: Fossa Chocolate)

A longstanding partnership with tea curators Pekoe & Imp has also resulted in amazingly fragrant tea chocolates, which are not made with your run of the mill cuppas, but with speciality teas such as Honey Orchid Dancong Hongcha, a naturally fruity and floral black tea cultivated on Phoenix Mountain in the Guangdong province of China.

“There aren’t any fine Chinese tea chocolates on the market,” Chia lamented. “There’s earl grey, English breakfast, but there’s no honey orchid hongcha, or honey orchid oolong. So that’s why we wanted to try to put all these teas into chocolate.”

The tea’s floral aromas led Fossa to pair it with the Kokoa Kamili cacao from Tanzania, resulting in a fragrant and complex chocolate that won gold at last year’s International Chocolate Awards.

(Image: Fossa Chocolate)

(Image: Fossa Chocolate)

Sadly, not every flavour can be made into chocolate. You likely won’t be seeing a chicken rice or beef rendang chocolate anytime soon, because many of their ingredients are too wet to be shelf stable, which is crucial for flavoured chocolates.

“Also, when we try to make the chocolate taste like a local dish, there’s a certain expectation to meet,” says Chia. “When locals taste it, they want the chocolate to remind them of the real dishes. So when we say that it’s a salted egg chocolate, it definitely must taste like salted egg.”

But one flavour that they are experimenting with should perk up some taste buds: mala. Yes, the folks at Fossa are trying to turn the spicy, numbing Szechuan flavour profile into a chocolate.

“The first few trials are pretty successful,” says Chua. “Really quite delicious, we’re just gonna do some fine tuning.”

Transcending Local Palates

Fossa is now available in several countries all over the world, with a significant portion of their revenues being generated overseas. This means that local flavours such as salted egg and chilli peanut are being savoured worldwide. In fact, Fossa credits these unique flavours with helping them reach an international audience.

(Image: Fossa Chocolate)

“We are very fortunate to have very good customers,” says Chua, “Some overseas customers actually bring our chocolate to their local favorite chocolate retailers and tell them that “hey, this chocolate is really nice, it’s from Singapore, you may want to look into connecting with them and bring in the chocolates.””

Today, a significant proportion of Fossa’ revenue is generated overseas. The wider reach has also enabled Fossa to move from their original facility in Tuas to a slightly larger one in Mandai and purchase machinery to help them make more chocolate.

Not everything has been smooth sailing — the main pressure point came when the trio quit their stable day jobs two years ago to devote their full attention to the business. “It was a huge step to take to quit my full-time job,” says Leong. “I think it was definitely very stressful. But I felt that it was either now or never. So we decided to take the leap.”

(Image: Fossa Chocolate)

As for where they see the company going in the future?

“We want to be a brand that a lot of people of our generation know,” Leong enthuses. “You may not have tried our chocolates. But at least you know that hey, Fossa Chocolate’s from Singapore, and it’s something to be proud of.”

Fossa Chocolate has shut down production operations during the circuit breaker, but its chocolates are still available for delivery at fossachocolate.com. Note that the delivery schedule may differ slightly from usual operations.

This is the first story in The Makers series, where we explore the many home-grown artisanal products and crafts that are quietly enriching Singapore’s cultural landscape. For more in this series, click here.